|

|

|

|

|

|

|

|

|

|

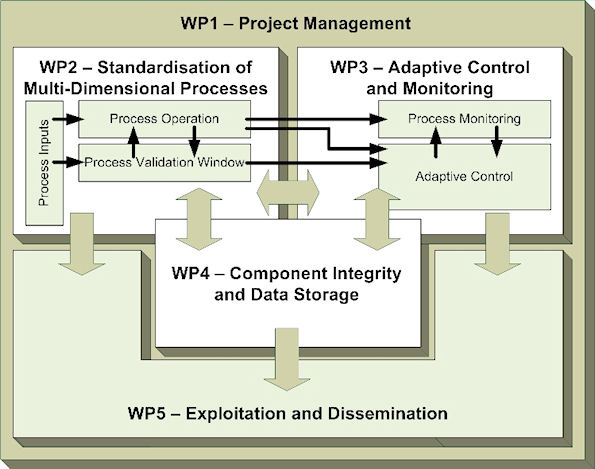

| Work packages |

|

WP1

The objectives of this work package are to ensure that the project is planned correctly and managed effectively, that all work packages are co-ordinated and deliver their defined objectives and deliverables, that effective exploitation of the project results is achieved, that Ethical, Gender, and Health, Safety and Environmental aspects are given due consideration, and that the consortium will foster good working relationships at both a personal and organisational level. To achieve these objectives, the work package will be organised into appropriate project management tasks as defined in the Description of Work.

WP2

This work package will ensure that a standard procedure will be generated within the project to generate a multi-dimensional machining process for new and existing materials. The main outcome will be a specification, which defines how a machining process has to be established and controlled in order to satisfy a defined surface integrity level. The connection of machining process parameter windows and surface integrity will be examined in this work package.

Three main areas will be addressed:

1. Definition and standardisation of process inputs.

2. Definition of process validation windows.

3. Characterisation of process operation dependencies.

WP3

This work package will deliver an understanding how to use process monitoring systems for a closed loop adaptive control system, which will keep the machining process with a defined process window. Based on the definitions and specified requirements of WP2, a system will be developed, which helps to keep a constant part quality (in terms of surface integrity) with an increased range of productivity. Robust machining processes with respect to variable boundary conditions (such as wear of tools, machining stability and variable forging quality) will be ensured due to the usage of process monitoring data out of the manufacturing testing sequence.

WP4

The approach taken in integrated surface engineering and design is to bring together those elements that have a direct effect on the component performance in terms of life and fitness for purpose. The interaction between the surface integrity generated as a result of the machining process parameters, cutting tool and machine tool condition, material characteristics, and post machining treatments such as etching and shot peening have to be investigated and understood. This knowledge will allow the design function to better understand the effect of machining processes and treatments on the part quality and subsequent component service, and also allow the component design to be optimised. In defining the component surface integrity requirements and the dependencies between surface integrity and manufacturing processes, the development of a surface integrity based part validation procedure can be realised. When validated, this procedure will allow better decision-making on part acceptability and hence significantly reduce inspection costs. In a similar manner, the effective communication of acceptable surface quality limits and technology to measure surface quality will allow production engineers to reduce new component introduction/development costs. With this new validation procedure, new demands will be placed upon the storage and retrieval of related data. Linkage between manufacturing process window parameters, desired surface integrity requirements, detection of process variation and correction within the control loop, and the final inspected surface integrity, will necessitate a review of current data storage capabilities and the development of new data management architecture.

WP5

The primary objective of this work package is to ensure that a framework exists whereby the consortiums industrial partners can directly exploit the results of the project, and that scientific research generated by the project can be exploited and disseminated by the consortium research organisations. Within this framework, intellectual property rights, rules regarding exploitation, and licensing of project deliverables will be formulated within a consortium agreement.

|

|

|

|

|

|

|

|

|

|

|